Both the “Curved Expander Roll (hereinafter referred to as Expander Roll)” and the “Concave Roll” are called “wrinkle removal rolls,” but what are the differences in their wrinkle expansion principles?

The Expander Roll uses “perpendicular entry + rubber expansion and contraction movement,” while the Concave Roll uses “peripheral speed difference + perpendicular entry” to expand wrinkles.

Expander Roll

Perpendicular Entry + Rubber Expansion and Contraction Movement

(in the case of Rubber Expander Roll)

【Perpendicular Entry】

When a sheet is conveyed with a sufficient wrap angle on a normal straight roll, it tends to move in a direction perpendicular to the roll axis (Figure 1). The same tendency occurs when the roll is angled. Therefore, the direction in which the sheet flows out is always perpendicular to the roll axis, and if the roll is angled, the flow-out direction changes (Figure 2).

The structure of the Expander Roll consists of a curved shaft with bearings embedded in it, around which a rotating bobbin is placed, covered with a cylindrical rubber. Therefore, while the central part of the curve tries to move straight, the ends move in the width direction, expanding and removing wrinkles (Figure 3).

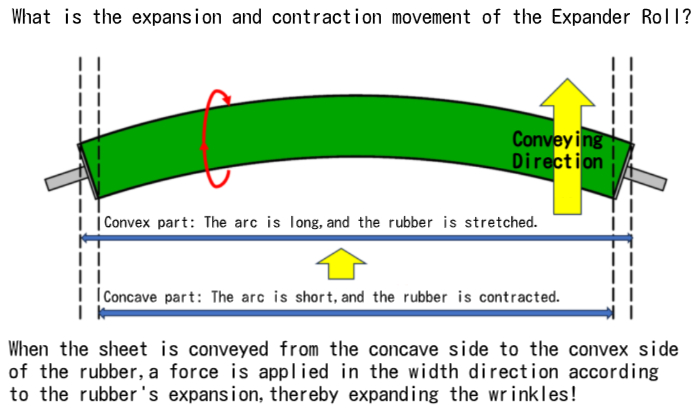

【Rubber Expansion and Contraction Movement】

As mentioned earlier, the Expander Roll is curved, so the rubber tube is contracted on the concave side and stretched on the convex side. When the roll diameter is rotated in this state, the rubber contracted on the concave side stretches as it moves towards the convex peak, and contracts again as it moves towards the concave side after passing the convex peak. In other words, the rubber expansion and contraction movement is constantly repeated during conveyance, and as the sheet enters from the concave part of the roll and flows out towards the convex part, the rubber stretches in both width directions, expanding the sheet and removing wrinkles.

Concave Roll

【Peripheral Speed Difference + Perpendicular Entry Due to Reverse Crown Shape】

The Concave Roll is a drum-shaped roll (reverse crown roll) where the central part is thinner (i.e., smaller roll diameter) than the ends. The diameter increases from the center towards the ends, meaning the circumference length becomes longer, so the conveyed material tends to move more at the ends (i.e., peripheral speed difference). In other words, the sheet is pulled by the force of the ends moving faster, expanding the wrinkles.

【Perpendicular Entry】

Like the Expander Roll, the Concave Roll also expects wrinkle expansion effects due to perpendicular entry.

Summary

|

This time, we explained the expansion principles of both the Expander Roll and the Concave Roll. While the Concave Roll often has micro-groove processing, our Expander Roll can also be processed with this feature, so please contact us. |

Additionally, our Expander Roll lineup includes a variable bow type, which, as the name suggests, has a variable curvature. The advantage of the variable bow type is that it can be adjusted for various situations such as changes in material thickness, width, and individual differences in raw materials with a single roll.

Product Introduction

|

Rubber Straight Variable Bow Expander Roll The amount of bow can be adjusted freely. The biggest feature is that the amount of bow can be set to 0. Thus, this expander roll can be used as a guide roll when it is unnecessary to set the bow. |

|

Rubber Compact Variable Bow Expander Roll This expander roll can be introduced even when the work space is limited because the jack is compact and stored in the frame. |

|

Variable Bow Expander Roll (Remote control operation) The amount of bow can be adjusted freely even during operation. |

Inquiries / requests for estimates by form

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。